The classification of raw materials of glass

Classification according to the composition of glass raw materials is currently the most common method, and the glass composition determines the performance of glass fibers.

Alkali metal oxide is one of the main components of glass. It generally refers to sodium oxide and potassium oxide. It mainly acts as a fluxing agent, which can reduce the melting point of silica from 1,700℃ to about 1000℃, which can save energy cost. However, as the alkali metal oxide content is increased, the properties such as chemical stability, electrical insulating properties and strength of the glass are reduced. Therefore, the application of glass fibers made of different alkali-containing glass components is quite different. According to the alkali metal oxide content of the glass, continuous glass fibers can be classified into the following types:

(1) Alkali-free glass fiber (E-grade glass fiber): The R2O content of alkali-free glass is less than 0.8% and belongs to aluminoborosilicate glass, which is the most widely used glass for glass fiber. The glass fiber has good chemical stability, electrical insulation properties and mechanical properties. However, the glass fiber is easily corroded by inorganic acids and is not suitable to use in acidic environment.

(2) Medium alkali glass fiber (C grade glass fiber): The R2O content of alkali glass is 11.6% to 12.4%, and belongs to soda lime silicate glass. The medium alkali glass fiber loses the electrical insulation performance due to the high alkali content, but the mechanical strength is still good (10% to 20% lower than the alkali-free glass fiber), but the chemical resistance, especially the acid resistance, is superior to the alkali-free glass fiber. Generally, the medium-alkali glass fiber in foreign countries contains a certain amount of boron trioxide, and the medium-alkali glass fiber in China is completely free of boron.

(3) High alkali glass fiber (Grade A fiberglass): the R2O content of high alkali glass is more than 15% and is a typical sodium silicate glass. The waste glass products, such as flat glass, glass bottles, bulbs, etc., are used as raw materials to make glass balls, and the glass fibers which are made into all high alkali glass fibers. High alkali glass is rarely used in the production of glass fibers due to its low strength, water resistance and alkali resistance.

Alkali-free glass fibers are widely used as reinforcing materials for insulating materials and FRP. Medium-alkali glass fiber has strong competitiveness because its lower in price than alkali-free glass fiber. In foreign countries, medium-alkali glass fiber is only used to produce corrosion-resistant glass fiber products, while in China, the medium alkali glass fiber accounts for more than half of glass fiber production, it’s widely used as latex cloth, filter cloth, woven fabric substrate, etc. It can also be used as a FRP reinforcement material with low requirements on electrical properties and strength.

Glass fibers made from other glass products can be collectively referred to as special glass fibers. The special glass fibers that have been commercialized are:

(1) Low dielectric glass fiber (D glass fiber): It is a glass fiber with a low dielectric constant and is suitable for use as a reinforcement for high-density printed circuit boards in modern electronic equipment.

(2) High-strength glass fiber (S-glass fiber): Because high-strength glass fiber has high strength, high modulus, heat resistance, impact resistance, high wave transmission and other excellent properties, it is used in high-performance composite materials such as aerospace, aviation, military, ship. However, due to the high price and low output, it is still not popular in the civilian sector.

(3) Alkali-resistant glass fiber (AR glass fiber): It is mainly used as a rib material for glass fiber reinforced concrete. It has good alkali resistance, which can effectively resist the erosion of high alkali substances in cement, and has excellent properties such as high modulus, high strength, heat resistance and impact resistance. It is environmental friendly reinforcing material in reinforced concrete which is widely used.

(4) Non-boron alkali-free glass fiber (E-CR glass fiber)

The classification of monofilament diameter

The glass fiber monofilament is cylindrical and its thickness can be expressed by diameter.

| Type | Monofilament diameter |

| Crude fiber | approximately 30 um |

| Primary fiber | more than 20 um |

| Medium fiber | 10~20 um |

| Advanced fiber | 3~10 um |

| Micro fiber | less than 4 um |

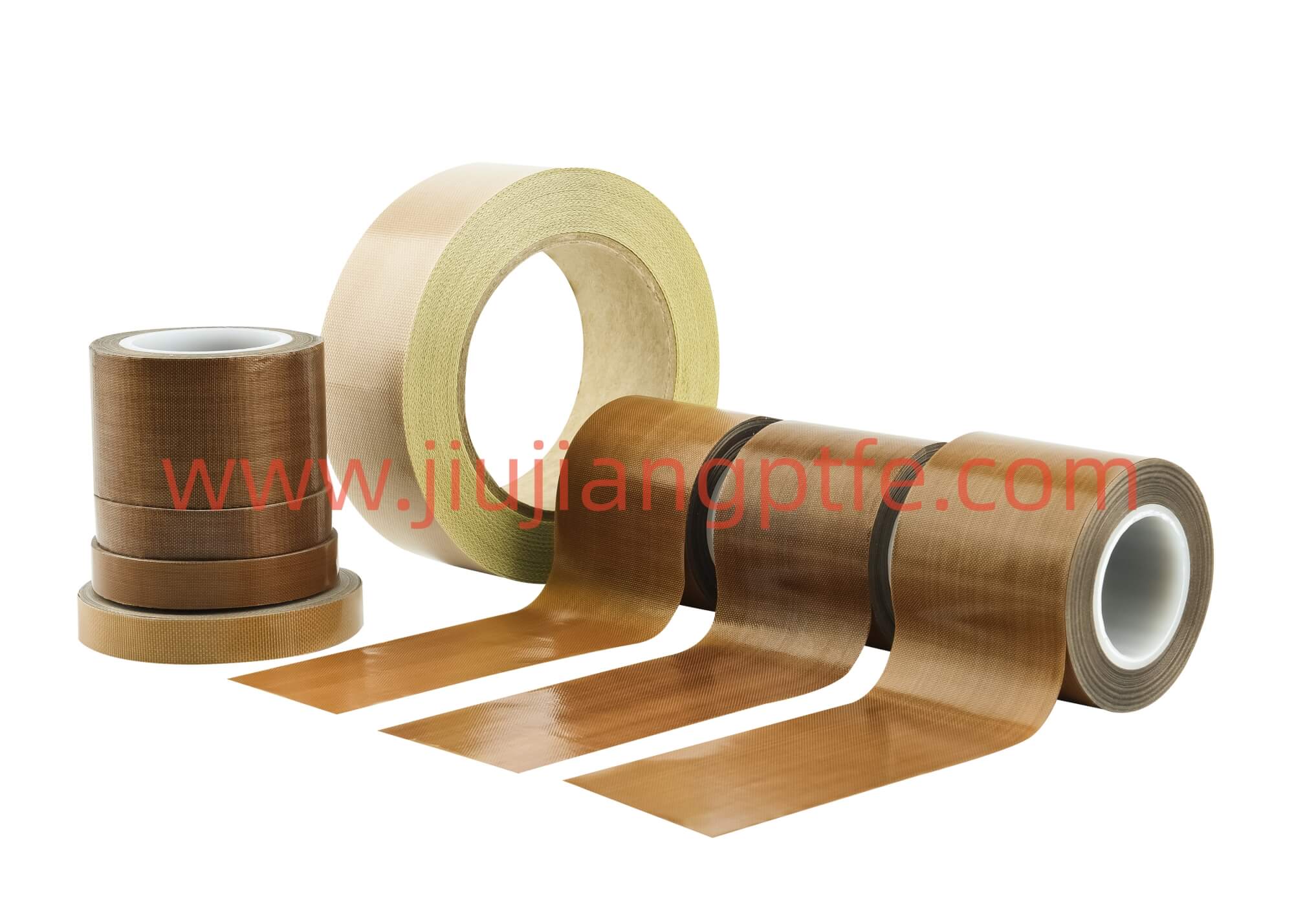

Differences in monofilament diameter can affect fiber performance, production process, and cost. The diameter of 5~10um fiber is generally made into textiles, such as fiberglass cloth, glass fiber belts, etc., 10~14um fiber is generally made into roving, non-woven fiberglass fabric, etc. The diameter of glass fiber produced internationally is getting thicker and thicker, generally 14~24um, and some even reach 27um.

The classification of appearance of fiber

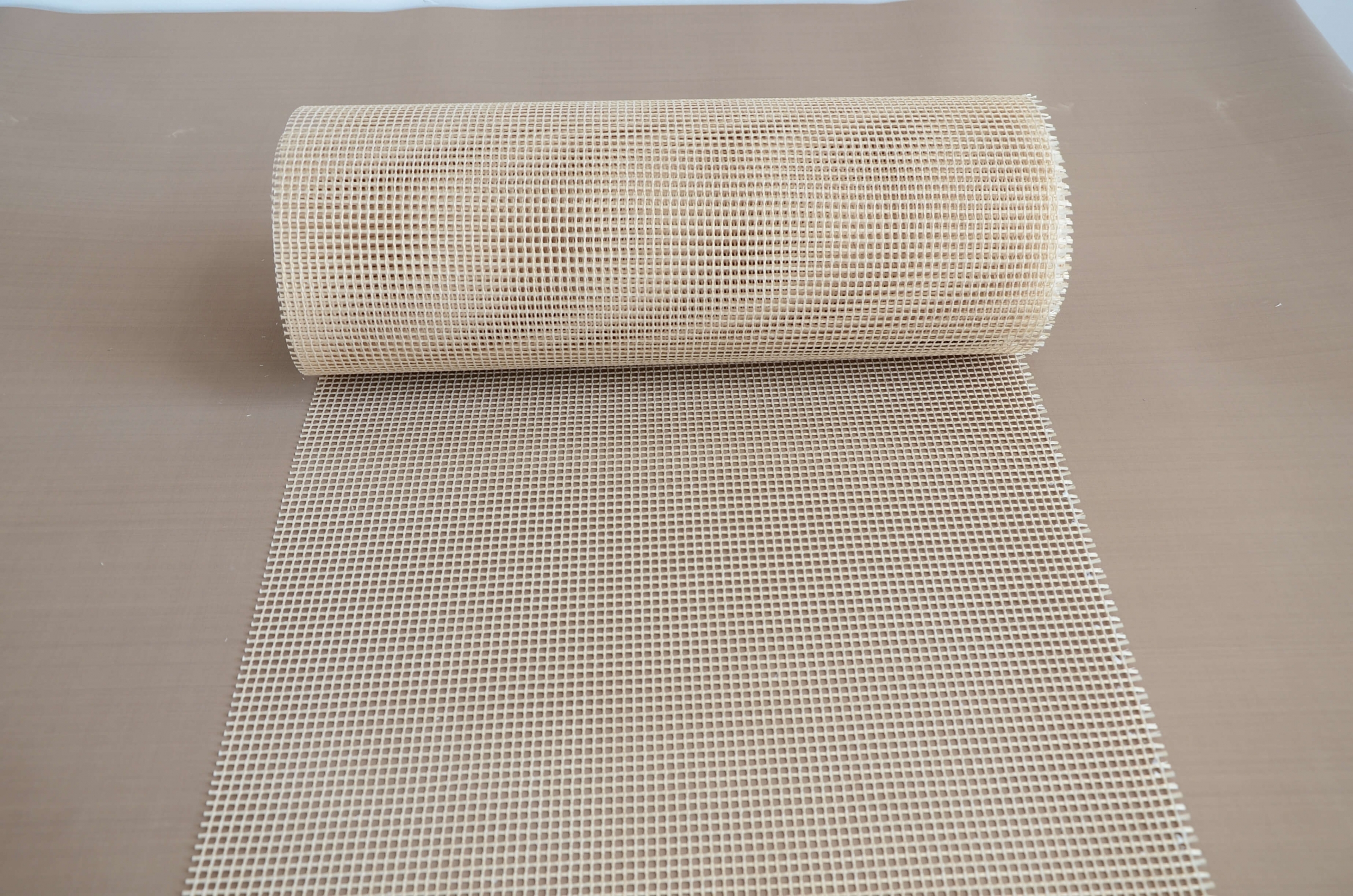

Glass fiber is made into different forms of products according to different needs.

(1) Continuous glass fiber: It is a long continuous strand or monofilament. Almost all of the continuous glass fibers produced are made from E glass. Continuous glass fiber has various forms of existence, such as roving, chopped strand, fabric, felt, etc., mainly used to reinforce thermosetting and thermoplastic resins in composite materials. In addition, continuous fibers are also known as textile fibers, so its second major use is in the manufacture of fiberglass textiles. Glass fiber textiles are mainly used in the electronics industry to manufacture printed circuit boards.

(2) Fixed-length glass fiber: the length is generally 300~500mm, and it is mostly made into yarn or mat.

(3) Glass wool: the length is generally less than 150mm, its shape is similar to cotton wool, fiber and fiber between the three-dimensional intersection, intertwined, with a large number of tiny space pores, which obtains good thermal insulation, sound absorption and noise reduction performance.

More: Fiberglass Fabric Manufacturing Process[/av_textblock]

[av_social_share title=” style=” buttons=” av_uid=’av-497xgw’ admin_preview_bg=”]

[/av_two_third][av_one_third min_height=” vertical_alignment=” space=” custom_margin=” margin=’0px’ link=” linktarget=” link_hover=” padding=’0px’ border=” border_color=” radius=’0px’ background=’bg_color’ background_color=” background_gradient_color1=” background_gradient_color2=” background_gradient_direction=’vertical’ src=” background_position=’top left’ background_repeat=’no-repeat’ animation=” mobile_breaking=” mobile_display=” av_uid=’av-hn6fp’]

[av_image src=’https://www.corefrp.com/wp-content/uploads/2018/06/logo.jpg’ attachment=’939′ attachment_size=’full’ align=’center’ styling=” hover=” link=” target=” caption=” font_size=” appearance=” overlay_opacity=’0.4′ overlay_color=’#000000′ overlay_text_color=’#ffffff’ copyright=” animation=’no-animation’ av_uid=’av-jisu3ztv’ admin_preview_bg=”][/av_image]

[av_icon_box position=’left’ icon_style=” boxed=” icon=’ue821′ font=’entypo-fontello’ title=’Shenzhen Core-Tex Composite Materials Co., Ltd.’ link=” linktarget=” linkelement=” font_color=” custom_title=” custom_content=” color=” custom_bg=” custom_font=” custom_border=” av-medium-font-size-title=” av-small-font-size-title=” av-mini-font-size-title=” av-medium-font-size=” av-small-font-size=” av-mini-font-size=” av_uid=’av-jlhn5f29′ admin_preview_bg=”][/av_icon_box]

[av_icon_box position=’left’ icon_style=” boxed=” icon=’ue854′ font=’entypo-fontello’ title=’+86-755-86540486′ link=” linktarget=” linkelement=” font_color=” custom_title=” custom_content=” color=” custom_bg=” custom_font=” custom_border=” av-medium-font-size-title=” av-small-font-size-title=” av-mini-font-size-title=” av-medium-font-size=” av-small-font-size=” av-mini-font-size=” av_uid=’av-jlhn5f29′ admin_preview_bg=”][/av_icon_box]

[av_icon_box position=’left’ icon_style=” boxed=” icon=’ue8ac’ font=’entypo-fontello’ title=’+86-136-6263-9827′ link=” linktarget=” linkelement=” font_color=” custom_title=” custom_content=” color=” custom_bg=” custom_font=” custom_border=” av-medium-font-size-title=” av-small-font-size-title=” av-mini-font-size-title=” av-medium-font-size=” av-small-font-size=” av-mini-font-size=” av_uid=’av-jlhn5f29′ admin_preview_bg=”][/av_icon_box]

[av_icon_box position=’left’ icon_style=” boxed=” icon=’ue805′ font=’entypo-fontello’ title=’[email protected]’ link=” linktarget=” linkelement=” font_color=” custom_title=” custom_content=” color=” custom_bg=” custom_font=” custom_border=” av-medium-font-size-title=” av-small-font-size-title=” av-mini-font-size-title=” av-medium-font-size=” av-small-font-size=” av-mini-font-size=” av_uid=’av-jlhn5f29′ admin_preview_bg=”][/av_icon_box]

[av_textblock size=” font_color=” color=” av-medium-font-size=” av-small-font-size=” av-mini-font-size=” av_uid=’av-jlhncgfy’ admin_preview_bg=”]

Address: Room 578, Zhongkang Office Building, Zhongkang Road, Futian District

Zip: 518000

Country/Region: China (Mainland)

Province/State: Guangdong

City: Shenzhen[/av_textblock]

[/av_one_third]