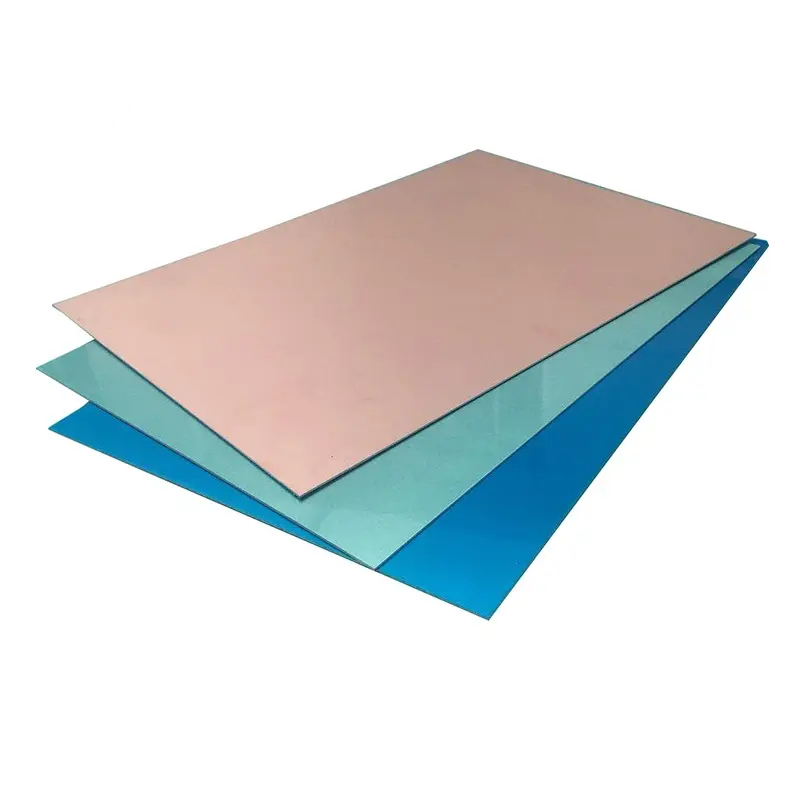

Ultimate Reliability

Ensuring Long-Lasting Durability in Electronics

Precision Engineering

Designed for Exacting Specifications and Standards

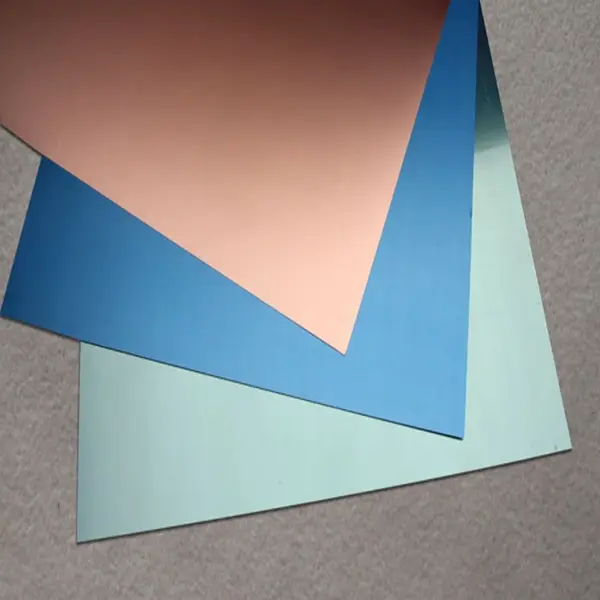

Innovative Solutions

Empowering the Next Generation of Electronics

OEM & ODM Service, Not Retailer

Custom Solutions, Your Brand’s Signature. Specializing in OEM & ODM, we transform ideas into market-ready products. Partner with us for quality and innovation tailored to your brand’s vision.

frequently asked questions

Unlocking Answers to Power Your Choices

Dive into Our Expert Insights for Seamless Solutions

OEM ODM Service, Not Retailer

Support Email