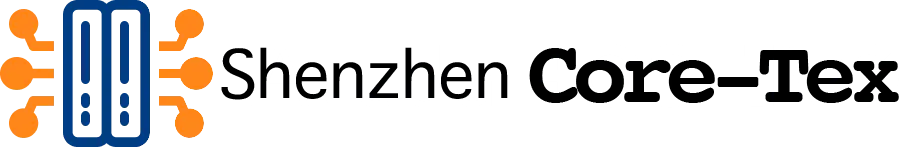

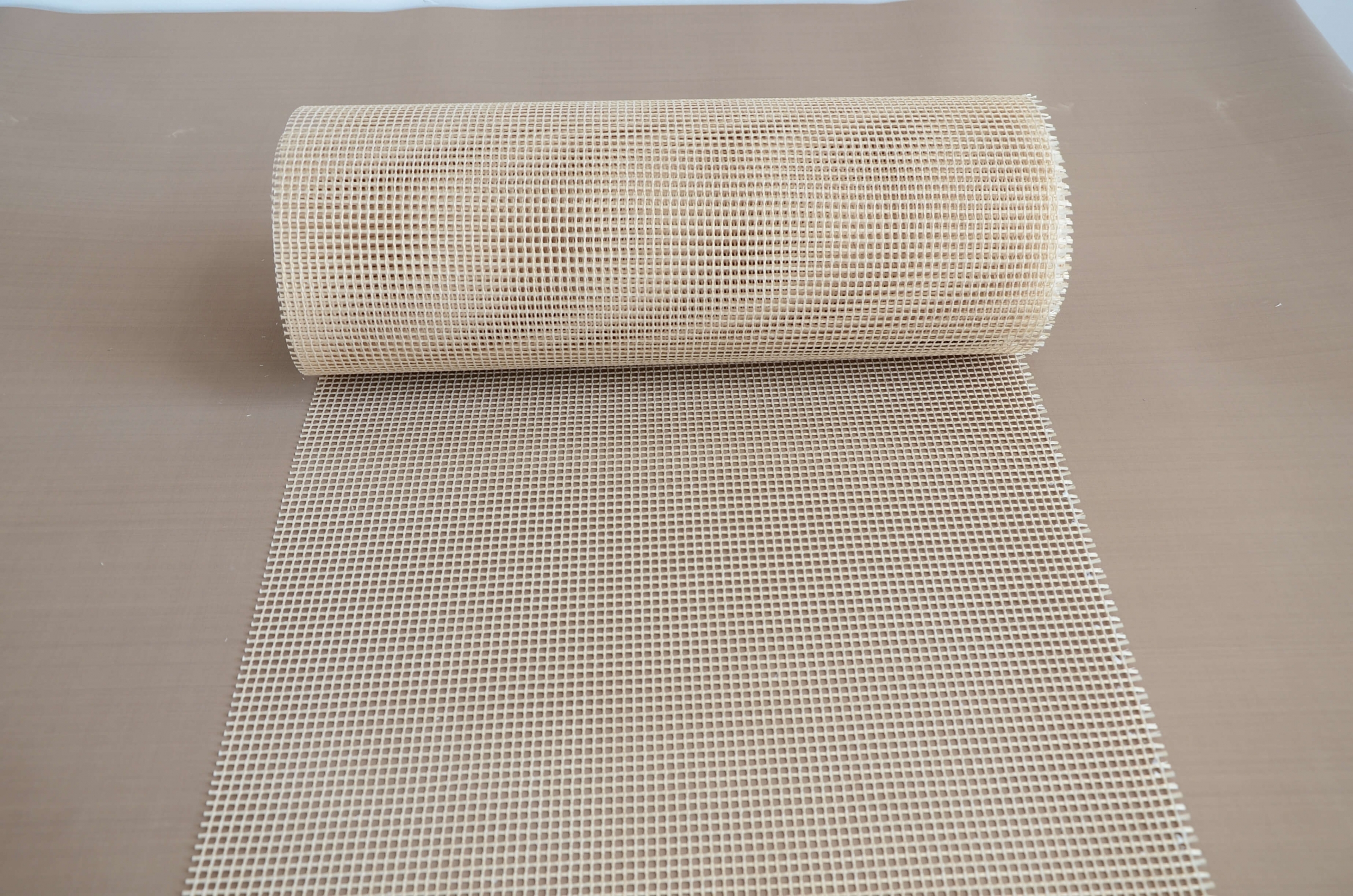

Teflon high temperature tape is made of high-quality glass fiber cloth, coated with PTFE resin on the surface, and coated with organic pressure-sensitive silica gel on one side to make high-quality Teflon high-temperature resistant tape.In order to avoid this phenomenon, it is necessary to operate correctly and import raw materials in production.

But glue residue phenomenon is a common phenomenon.

After the Teflon tape is subjected to high temperature, there will be residual glue, glue overflow, degumming and other phenomena. Through close observation, it will be found that there are tiny residues, which have a great impact on production.If the temperature is too high and it is not within the scope of the process requirements, there will also be residual glue phenomenon, and you should check whether the temperature sensor is normal; however, the Teflon high temperature tape product itself has quality problems, and the pressure is not strictly followed in the coating production process. The baking data of the sensitive adhesive is heated and cured, and the curing time is not enough or the coating line speed is too fast, which will cause the glue, the primer glue, and the substrate to be unable to combine the components;When the Teflon tape is formed, the semi-finished roll material needs to stand for 2-3 days before the tape can be re-rolled, and then cut and used, mainly to fully combine the glue and the substrate, so that the glue can be in a natural state Fully cured, if the rewind tape is slit without complete curing, residual adhesive will appear.

If there is residual glue phenomena in the production process, the problematic workpiece should be taken out and placed separately. In order to avoid such phenomenon, the online products should be checked more intensively, and analyzed through a period of time or a certain number of bad statistics. The percentage of residual glue rate should also be checked according to the actual situation of this batch of tapes to find out the root cause of the problem, so that similar phenomena will not occur in the production process.

Therefore, the production process of Teflon tape should also be strictly carried out. Once a problem occurs, it will cause waste of resources and delay production.

It can be seen that the phenomenon of residual glue in Teflon tape is very common. The reason may be the problem of raw materials, or it may be a problem in production. In addition, it may be that the temperature is too high during use, which exceeds the high temperature Teflon tape can withstand.

If there is a problem with the quality of the tape, the customer should not panic and contact the manufacturer to solve this problem.

- First, confirm whether the high temperature resistance data of the Teflon tape in use meets the production requirements, usually requiring a temperature resistance of 210 degrees to 260 degrees.

- Whether the temperature data of the production line is within the range of process requirements, whether the temperature is too high, check whether the temperature sensor is normal.

- In view of the quality problems of the Teflon tape product itself, whether the Teflon tape is heated and cured in strict accordance with the pressure-sensitive adhesive baking data during the coating production process, the curing time is not enough or the coating line speed is too fast, it will As a result, the glue, primer glue and substrate cannot be combined.

- After the Teflon tape is coated, the semi-finished product should be left for 2-3 days before rewinding and slitting. The purpose is to fully combine the glue with the substrate, and the glue will be completely cured in a natural state;