A variety of high temperature resistant tapes are usually used in painting, lacquered leather processing, painting masking and fixing in the process of electronic parts, PCB and high temperature processing masking. These working environments are generally between 120 degrees Celsius and 260 degrees Celsius, and some extreme environments require 400 degrees Celsius. When using tape in a high temperature working environment, it is necessary to consider not only the temperature resistance, but also the characteristics of the tape itself, such as insulation and food grade requirements.

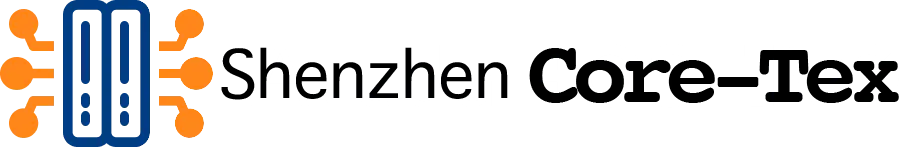

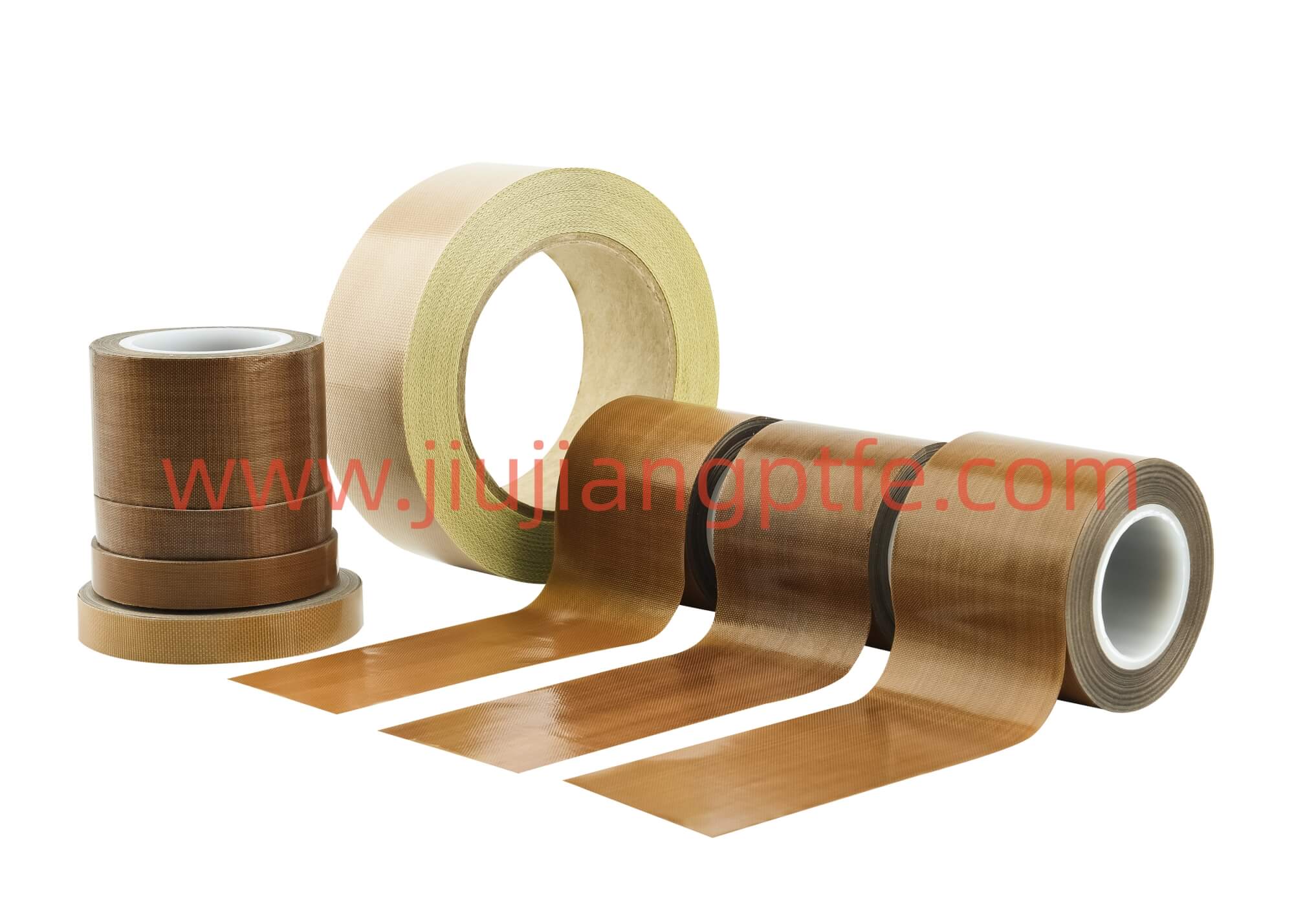

Common high temperature tape

KAPTON high temperature tape, PTTFE high temperature tape, high temperature masking tape, PET green high temperature tape, high temperature double-sided tape, etc.

Take PTFE high temperature tape as an example, which has the following characteristics:

1. Non-stick;

2. High and low temperature resistance, the long-term use of the product can reach 260 degrees Celsius;

3. Corrosion resistance;

4. Low friction and wear resistance;

5. Moisture resistance, high insulation;

6. Thickness: 0.13mm, 0.18mm and 0.25mm;

7. Colors are brown and black.

The temperature resistance of the tape

High-temperature tape is mainly composed of two parts: base material and glue. Some manufacturers take certain measures to reduce costs, so that the quality is greatly reduced. Taking KAPTON high temperature tape as an example, the temperature resistance and insulation performance of the fake tape are far lower. The actual base material used is brown PET film coated with silicone. The temperature of the actual application in the industry does not reach 260°, and the maximum temperature resistance of PET is 220°, so it is not easy to find. What’s more, other glues are used instead of silicone, and its temperature resistance is far less than 150°.

Identify the high temperature from several points

1. Smell;

2. Appearance;

3. Residues after ignition and combustion;

4. High temperature test: treat it at 260°, and check whether there is residual glue, shrinkage, etc.

Storage, use and maintenance

1. The tape should be stored in the warehouse to avoid sunlight and rain; it is forbidden to contact with acid-base oil and organic solvents, keep it clean and dry, and the room temperature is between -15℃~40℃, 1m away from the discovery device.

2. The tape should be placed in rolls without folding, and should be turned over quarterly when the storage time is too long.

3. Use a crane, and use a rigging with a beam to hoist it smoothly to avoid damage to the edge of the tape.

4. The type and specification of the tape should be reasonably selected according to the use needs and specific conditions.

5. It is not allowed to connect (match) tapes of different varieties, specifications, models, strengths and layers of cloth together.

6. The conveyor belt joint should preferably be bonded by hot vulcanization to improve reliability and maintain a high effective strength.

7. The diameter of the conveying roller of the conveyor and the minimum diameter of the pulley of the conveying belt shall comply with the relevant regulations.

8. Do not make the tape meander or creep, keep the drag roller and vertical roller flexible, and the tension should be moderate.

9. When the conveyor is equipped with baffles and cleaning devices, wear and tear of the belt should be avoided.

10. Cleanliness is the basic condition for the good operation of the tape, or it leads to tension difference, and even break.

11. When the tape is found to be damaged early in use, the cause should be found and repaired in time to avoid adverse consequences.