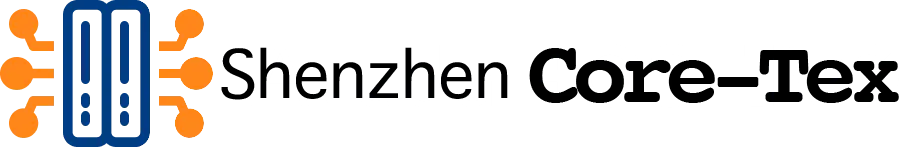

As a factory specializing in R&D and production of Teflon coated fiberglass fabric, our engineers often receive inquiries from customers and colleagues as to why some Teflon coated fiberglass fabric has insufficient strength.

The use of Teflon coated fiberglass fabric with insufficient strength may tear, which directly affects the use of the product. We have sorted out the following aspects about the reasons that affect the strength of Teflon coated fiberglass cloth. You can refer to these reasons for improvement and avoid the production of insufficient strength Teflon coated fiberglass fabric in the process of producing Teflon coated fiberglass fabric.

Reasons that affect the strength of Teflon coated fiberglass fabric

1.The strength of glass fiber yarn directly affect the strength of Teflon coated fiberglass cloth.

Teflon coated fiberglass fabric is based on glass fiber cloth. The strength of glass fiber cloth directly determines the strength of Teflon coated fiberglass fabric, and the strength of glass fiber yarn determines the strength of glass fiber cloth.

Before the glass fiber yarn is woven into the glass fiber cloth, there will be a desizing process. This process will affect the combination of the finished glass fiber cloth and the Teflon emulsion. If the desizing is abnormal, it will affect the adhesion of the Teflon coating.

In the selection of raw materials, we must buy qualified glass fiber cloth.

2. Quality control in the production process of Teflon coated fiberglass fabric affects the strength of the coated fiberglass fabric.

In the process of combining glass fiber cloth and Teflon emulsion, the glass fiber cloth is in a high temperature environment. It is necessary to have enough temperature to ensure the full combination of Teflon emulsion and glass fiber cloth. It is also necessary to prevent damage to the glass fiber cloth caused by excessive temperature.

If abnormal production equipment or improper operation by personnel causes the high temperature to last too long, it may affect the hardness and strength of the glass fiber cloth, and the strength of the produced Teflon coated fiberglass fabric will be unqualified.

The temperature change adjustment and time control of the drying process are very important.

3.The packaging, transportation and storage of the finished Teflon coated fiberglass fabric will affect the strength of the Teflon coated fiberglass fabric.

Whether it is packing, transportation, or storage, the operator must handle it carefully to prevent creases on the surface of the Teflon coated fiberglass fabric. Once there are creases, the abnormal quality of the Teflon coated fiberglass fabric during repeated use is almost all due to the existence of the crease, and the Teflon coated fiberglass fabric tears from the crease.

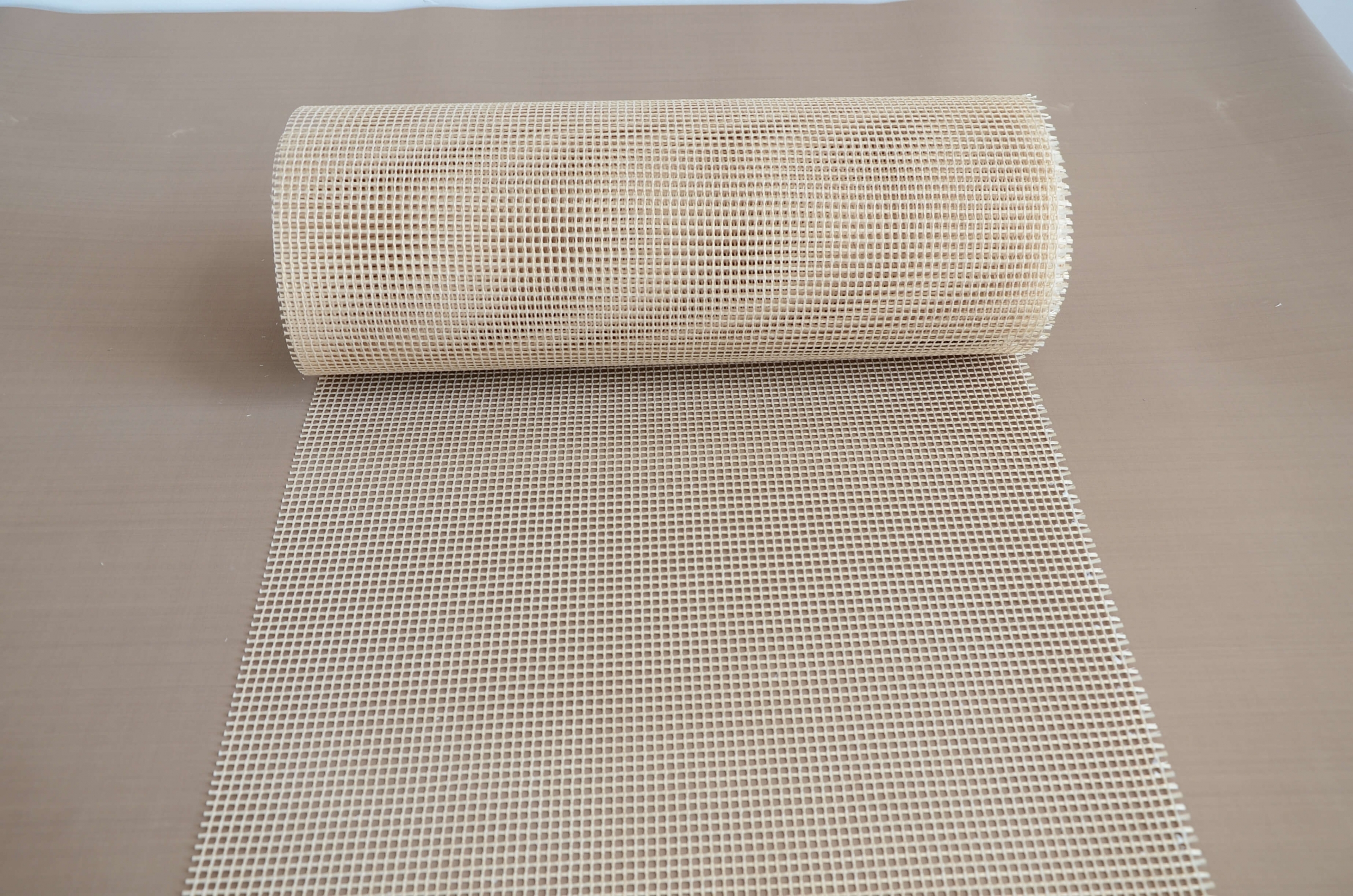

The above is a summary of our engineers from the insufficient strength of Teflon coated fiberglass fabric in the market. If you have any abnormalities in the process of using Teflon coated fiberglass fabric, please contact us at [email protected], and we also provide Free samples of Teflon coated fiberglass fabric, Teflon conveyor belt, Teflon tape and other products.