The Printed Circuit Board (PCB) is the backbone of modern electronic devices, providing mechanical support and electrical connections for electronic components. Selecting the right material for PCB manufacturing is crucial to ensure the performance, reliability, and longevity of electronic devices. One of the most popular and widely used materials for PCBs is FR4. In this article, we will explore the properties and benefits of using FR4 as a PCB material and why it is considered the ultimate choice for many electronic applications.

What is FR4?

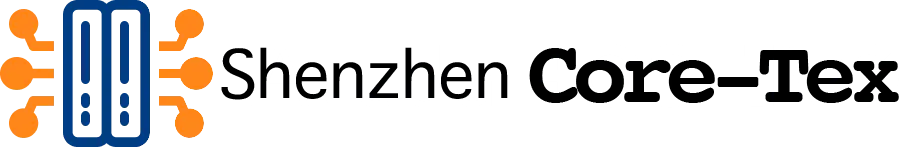

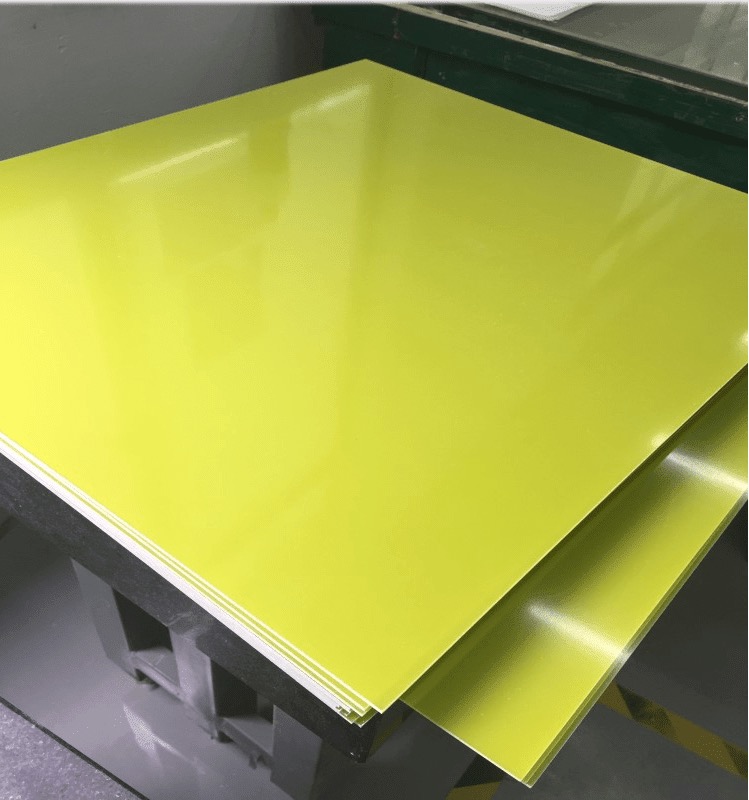

FR4 is a grade designation for Flame Retardant fiberglass reinforced epoxy laminate sheets. It is a composite material made by impregnating layers of woven fiberglass with epoxy resin and then pressing them together under high heat and pressure. This process results in a robust, stable, and highly insulating material that can withstand a wide range of demanding applications and challenging environments.

Key Properties of FR4 as a PCB Material

1. Exceptional Electrical Insulation: FR4 exhibits outstanding electrical insulation properties, making it perfect for use in electronic devices and electrical systems. It helps prevent electrical arcing, short-circuiting, and other electrical hazards, ensuring the safety and reliability of your electronic devices.

2. High Mechanical Strength: FR4 sheets possess excellent mechanical strength, which is essential for providing adequate mechanical support for electronic components mounted on the PCB. This ensures that the PCB can endure high levels of stress without compromising its structural integrity.

3. Flame Retardancy: As the name suggests, FR4 has flame-retardant properties, making it suitable for applications where fire safety is crucial, such as consumer electronics, aerospace, and transportation industries.

4. Dimensional Stability: FR4 maintains its shape and size, even under extreme temperature and humidity conditions. This ensures that PCBs made from FR4 will maintain their precise dimensions, guaranteeing a perfect fit and reliable performance.

5. Thermal Performance: FR4 has a high glass transition temperature (Tg), allowing it to withstand continuous exposure to high temperatures without significant changes in its mechanical and electrical properties. This ensures that PCBs made from FR4 can maintain their performance even in high-temperature environments.

Benefits of Using FR4 as a PCB Material

1. Cost-Effectiveness: FR4 is a cost-effective choice for PCB manufacturing, offering excellent performance at a relatively low cost. This makes it an attractive option for a wide range of applications, from consumer electronics to industrial equipment.

2. Versatility: FR4 is compatible with various manufacturing processes, such as through-hole technology (THT), surface mount technology (SMT), and multilayer PCB fabrication. This makes it suitable for a wide range of electronic devices and applications.

3. Wide Availability: Due to its popularity, FR4 is readily available from a variety of suppliers, ensuring a consistent supply chain for your PCB manufacturing needs.

4. Environmentally Friendly: FR4 is a more environmentally friendly option compared to other PCB materials, such as phenolic paper laminates, due to its reduced impact on the environment during manufacturing and disposal.

FR4 is a reliable, high-performance, and cost-effective choice for PCB material, offering exceptional electrical insulation, mechanical strength, flame retardancy, and thermal performance. Its versatility and wide availability make it the ultimate choice for many electronic applications.

If you are looking for a PCB material that offers the perfect balance between performance, cost, and reliability, look no further than FR4.