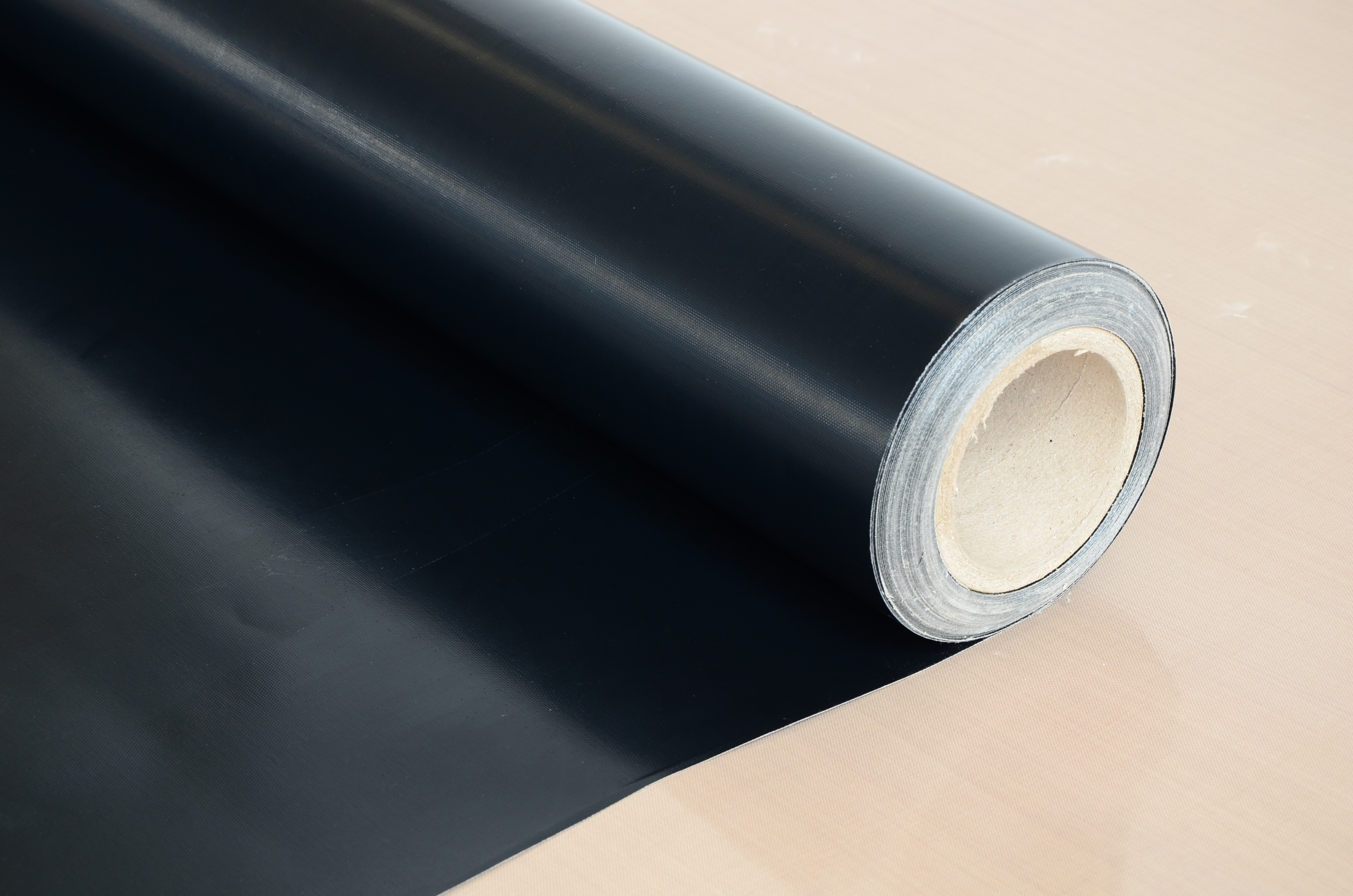

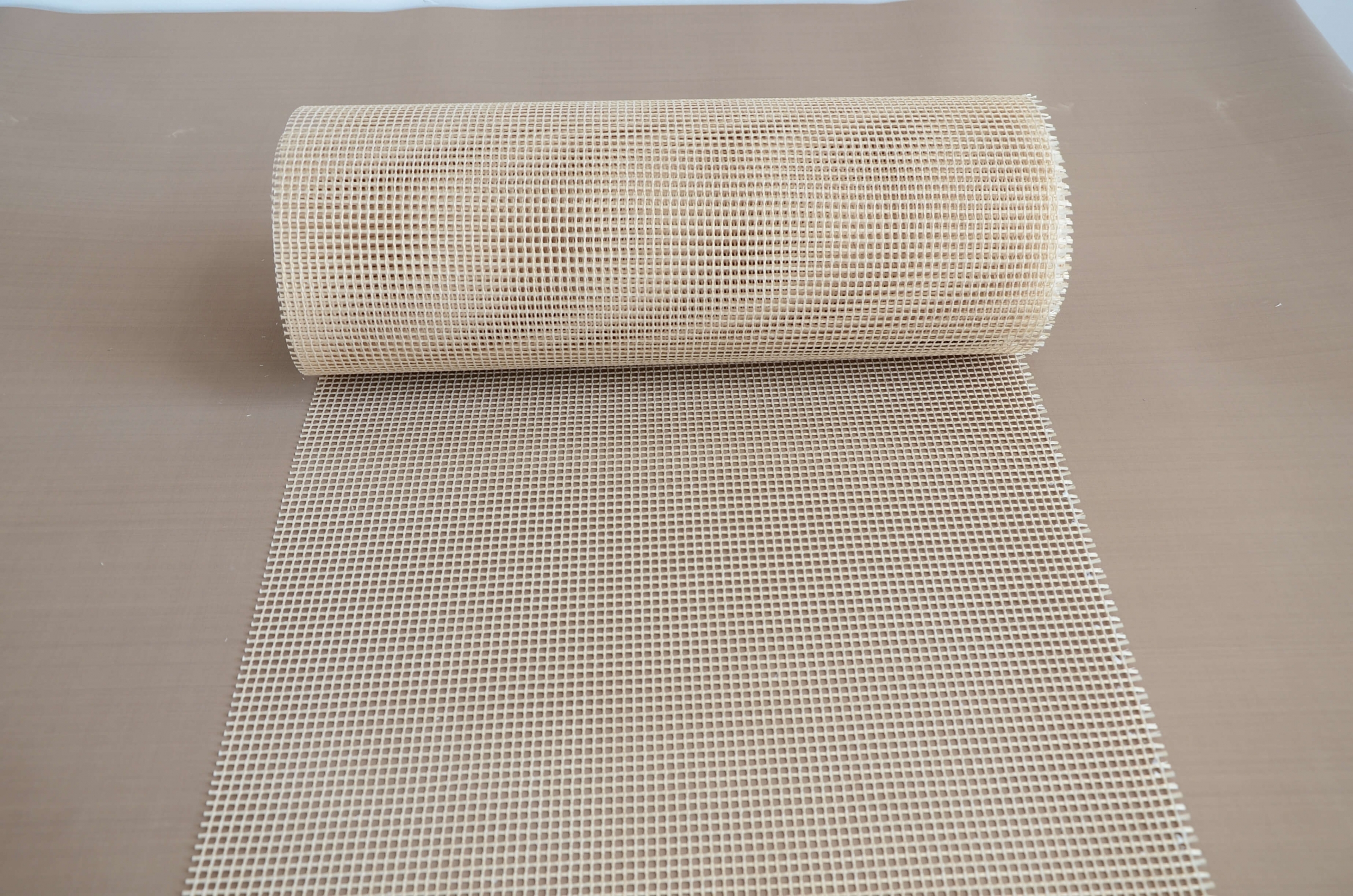

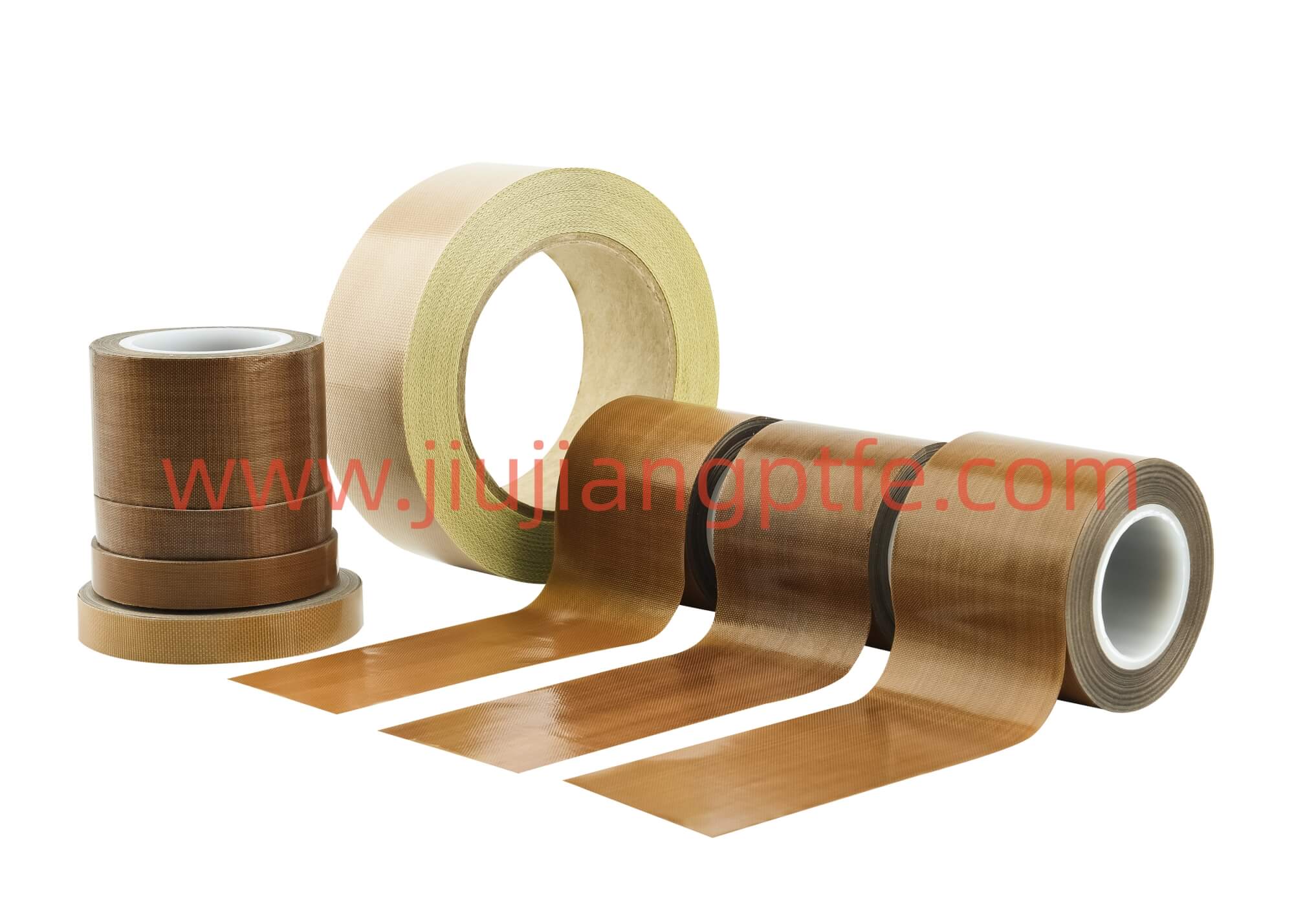

The surface of Teflon coated fiberglass fabric is smooth and high temperature resistant, and it is not easy to stick to other items. At the same time, it comes with food-grade safety and is very versatile. Ordinary Teflon coated fiberglass fabric is mainly based on the three characteristics of high temperature resistance, smooth non-stickiness and food-grade safety. But some scenes need to use special Teflon coated fiberglass fabric, for example, in an electrostatic environment, you need to choose anti-static Teflon coated fiberglass fabric.

- How to make Teflon coated fiberglass fabric with anti-static function

In order to have anti-static function, ordinary Teflon coated fiberglass fabric usually uses two different solutions to deal with: adding graphite or adding anti-static agent, After treatment, the anti-static Teflon coated fiberglass fabric can make the anti-static coefficient to the 6th power of 10. This grade of Teflon coated fiberglass fabric is specially customized and can meet the use of various anti-static environments.

- What are the effects if there is no anti-static?

For the electronics industry, static electricity will attract dust, aging sophisticated electronic components, and even breakdown integrated circuits. It can cause electronic equipment failure and electromagnetic interference.

High-voltage electrostatic discharge may cause electric shock, endangering personal safety. In the vicinity of flammable and explosive products or dust, oil mist and other production places, a slight careless cause of static electricity or even sparks can easily cause explosions and fires.

In the film and plastics, paper making, printing and textile industries, static electricity can cause uneven winding of film and film, or uneven winding of paper, inaccurate overprinting, serious dirt absorption, even the paper sticks, or causes the strands to flutter, entangled flowers, break ends, and yarn tangles.

The common Teflon coated fiberglass fabric can withstand a temperature of 210-260 degrees Celsius. In the conventional Teflon coated fiberglass fabric manufacturing process, if the temperature exceeds this temperature, there will be residual glue and glue overflow. At this time, you will find tiny residues by hand feeling or close observation. This kind of tiny residue has a great impact on production, and the produced Teflon coated fiberglass fabric is prone to substandard quality.

In order to maintain quality and quantity, it is recommended to consider the impact of various static electricity on production when planning equipment installation in the factory to avoid production abnormalities in the later period. In order to satisfy the company’s future production of higher quality Teflon coated fiberglass fabric, the production site should also pay attention to the influence of static electricity.

Contact us at [email protected] for free samples of anti-static Teflon coated fiberglass fabric.